Industrial machinery industry

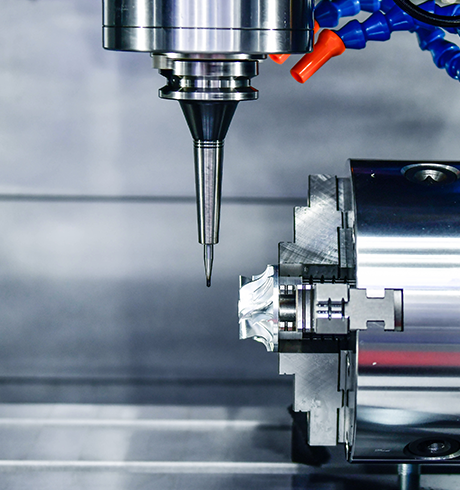

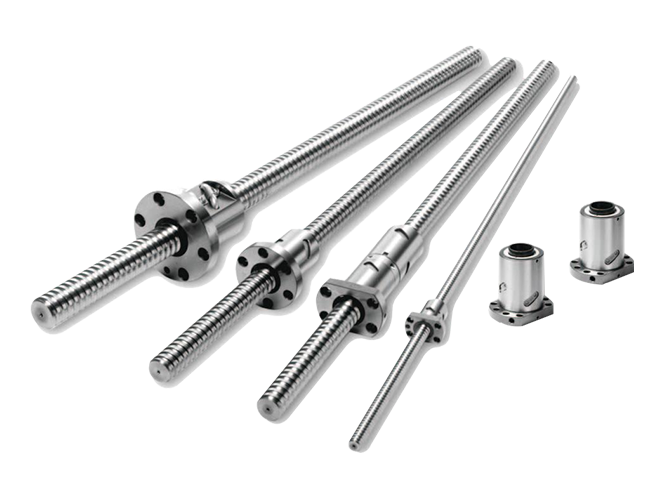

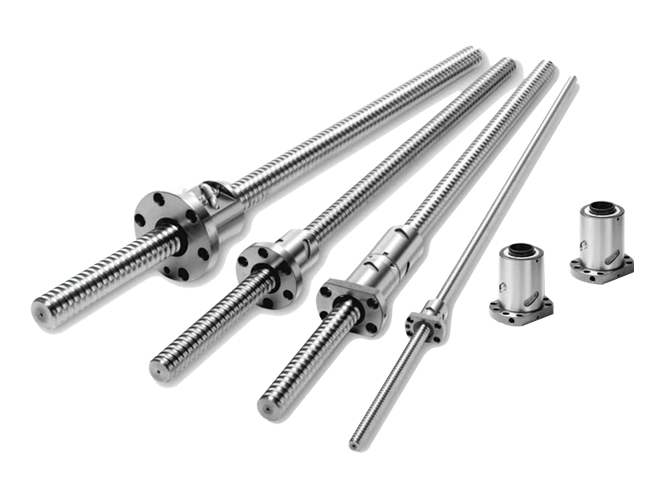

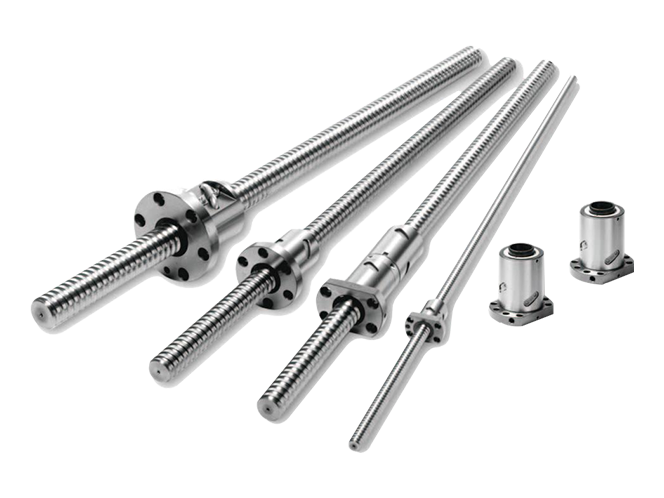

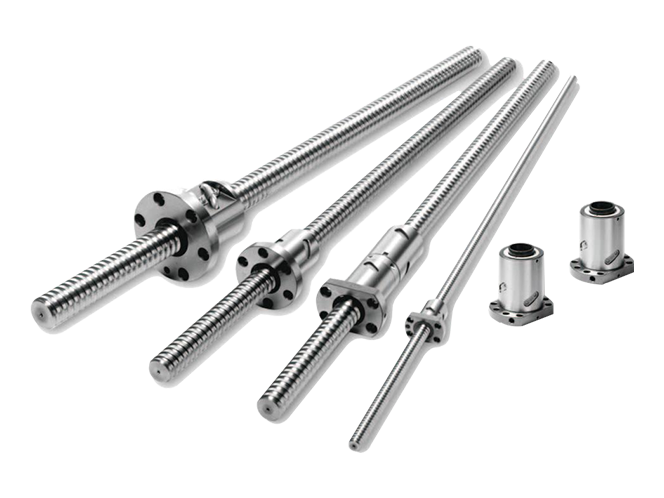

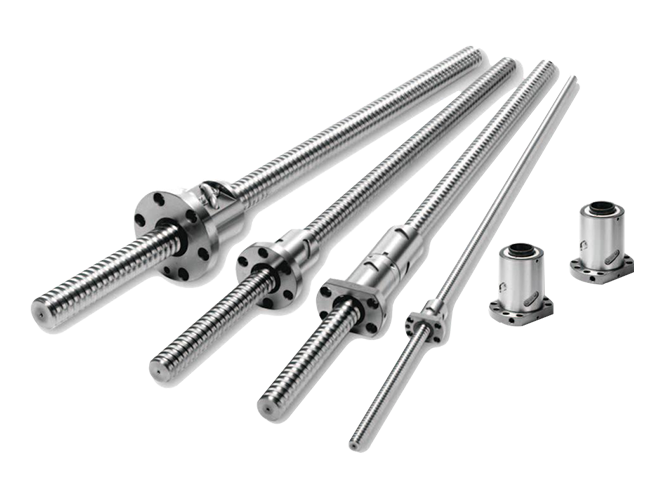

In mechanical processing, ball screws are used in the spindle drive system of CNC machine tools to achieve high-speed and high-precision cutting operations. In the production of electronic devices, ball screws are used as transmission devices on precision assembly lines to ensure precise alignment and assembly quality of components.

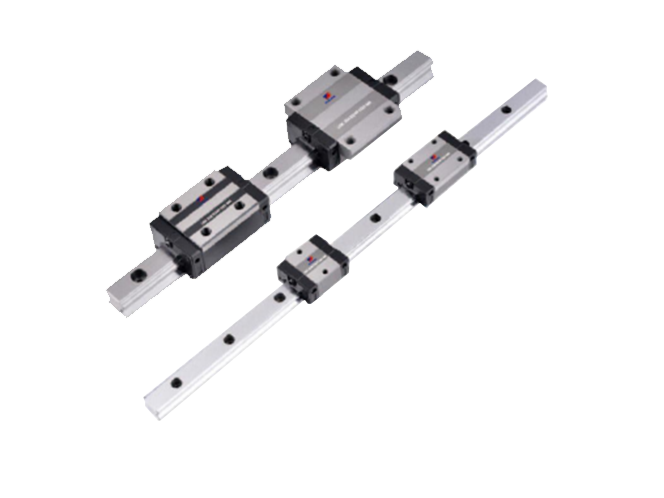

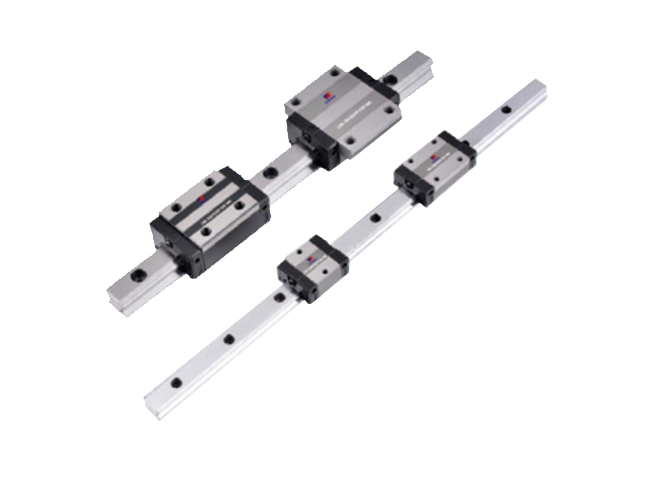

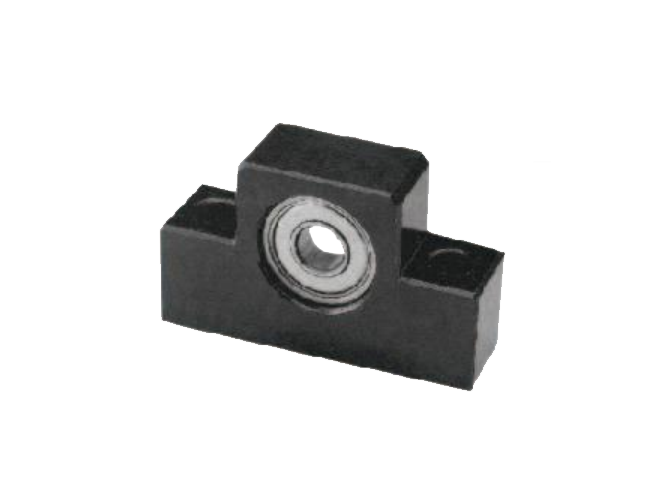

Ball screws have many advantages in automated production lines. Has high transmission efficiency and smooth motion. The ball screw adopts a contact transmission method between the ball and the screw thread, which has lower friction loss and higher transmission efficiency compared to sliding transmission. The rolling motion of the ball screw makes the transmission process smoother, reduces the generation of vibration and noise, and improves the comfort of the working environment. Ball screws have a longer service life and lower maintenance costs. Due to the use of rolling contact, the friction loss of the ball screw is smaller compared to sliding contact, which can extend its service life, reduce maintenance frequency and cost. Ball screws also have high rigidity and load-bearing capacity, which can withstand large loads and impacts.

Contact us